Technical Description

Technical description:

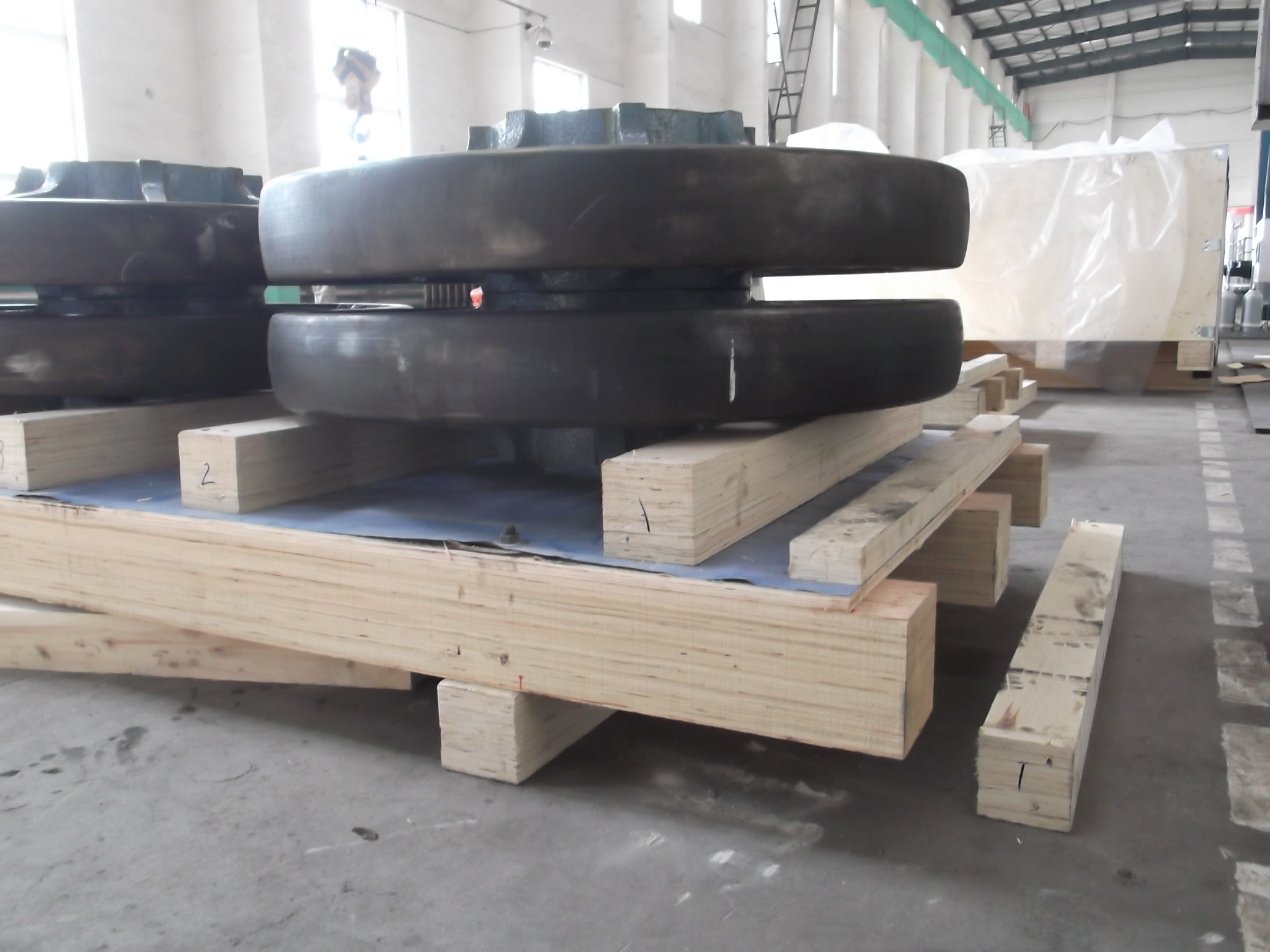

Support wheel, also called track roller.

Because the mining shovel is operating in large-scale open pit, the operating temperature greatly changes with the seasons, the support wheels withstand the weight of machine and loadings, and also with high manganese steel crawler shoes at contact and conflict, and extremely bad working environment, so the high hardness on surface, good matrix strength, good overall performance and low-temperature toughness are required in order to improve the usage performance and life.

(Support wheel is a main part in excavator loading under the bad environment, because it is contact with track, so it has a higher requirement on the rim of the wear resistance, fatigue resistance and impact resistance. Suitable heat treatment is to obtain the desired mechanical properties of the support wheel, safe and effective work, so the study of rollers heat treatment process is particularly important. My company is mainly studying the technology of heat treatment of support wheel for heavy mining equipment so that find out the stable technology programs and technical parameters for meeting the blooming demand and improving the lifetime continually. )

Manufacturing process:

Melting- casting- rough machining- heat treatment- final machining

Advantage:

1. High hardness on surface

2. Sound matrix strength

3. Low temperature toughness

4. Long lifetime

5. Sound mechanical properties

Technical parameters:

Weight:930kg,825KG

Material:ZG34Cr2Ni2Mo

Support wheel, also called track roller.

Because the mining shovel is operating in large-scale open pit, the operating temperature greatly changes with the seasons, the support wheels withstand the weight of machine and loadings, and also with high manganese steel crawler shoes at contact and conflict, and extremely bad working environment, so the high hardness on surface, good matrix strength, good overall performance and low-temperature toughness are required in order to improve the usage performance and life.

(Support wheel is a main part in excavator loading under the bad environment, because it is contact with track, so it has a higher requirement on the rim of the wear resistance, fatigue resistance and impact resistance. Suitable heat treatment is to obtain the desired mechanical properties of the support wheel, safe and effective work, so the study of rollers heat treatment process is particularly important. My company is mainly studying the technology of heat treatment of support wheel for heavy mining equipment so that find out the stable technology programs and technical parameters for meeting the blooming demand and improving the lifetime continually. )

Manufacturing process:

Melting- casting- rough machining- heat treatment- final machining

Advantage:

1. High hardness on surface

2. Sound matrix strength

3. Low temperature toughness

4. Long lifetime

5. Sound mechanical properties

Technical parameters:

Weight:930kg,825KG

Material:ZG34Cr2Ni2Mo